Customer: Aluro Machines

Solution: Reniway Edge

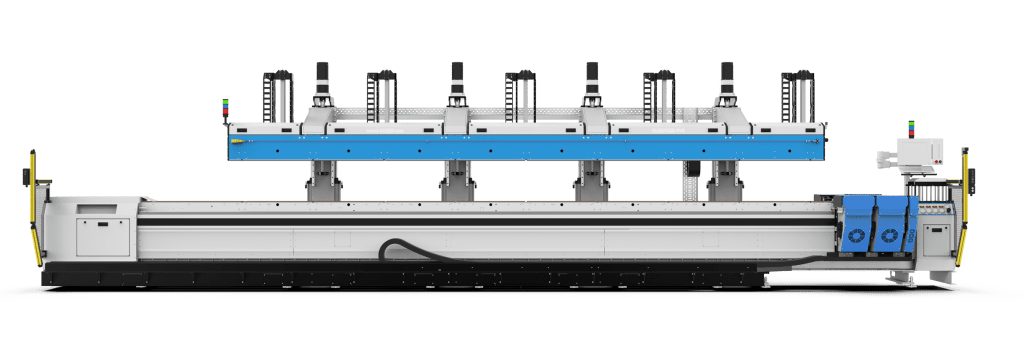

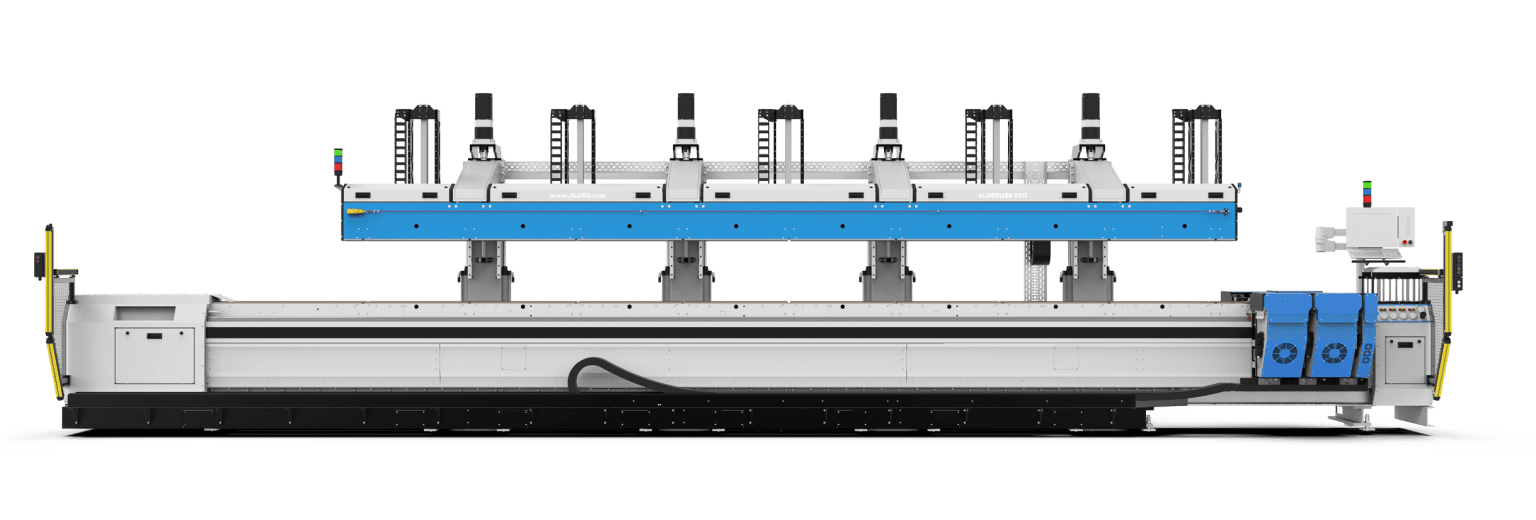

Aluro designs and builds advanced machines for processing aluminum profiles, with a strong focus on thermal break insertion and automation solutions for extrusion companies worldwide.

As their customers modernize operations, there is growing demand for machines that not only perform mechanically but also integrate digitally with MES, ERP, and monitoring systems. However, the customized nature of Aluro’s machines makes it difficult to standardize data and create plug-and-play digital interfaces. This complicates integration and limits opportunities for remote diagnostics, predictive maintenance, and scalable after-sales services.

Aluro designs and builds advanced machines for processing aluminum profiles, with a strong focus on thermal break insertion and automation solutions for extrusion companies worldwide.

As their customers modernize operations, there is growing demand for machines that not only perform mechanically but also integrate digitally with MES, ERP, and monitoring systems. However, the customized nature of Aluro’s machines makes it difficult to standardize data and create plug-and-play digital interfaces. This complicates integration and limits opportunities for remote diagnostics, predictive maintenance, and scalable after-sales services.

The goal for Aluro was to equip their machines with a smart, standardized interface that could meet modern integration and connectivity demands. This would allow them to:

Ensure seamless integration with their customers’ MES, ERP, and other IT systems.

Streamline deployment in diverse production environments, despite machine customization.

Provide real-time operational insights directly from the machine.

Enable advanced services such as predictive maintenance and remote diagnostics.

Lay the foundation for scalable, data-driven after-sales support.

The goal for Aluro was to equip their machines with a smart, standardized interface that could meet modern integration and connectivity demands. This would allow them to:

Ensure seamless integration with their customers’ MES, ERP, and other IT systems.

Streamline deployment in diverse production environments, despite machine customization.

Provide real-time operational insights directly from the machine.

Enable advanced services such as predictive maintenance and remote diagnostics.

Lay the foundation for scalable, data-driven after-sales support.

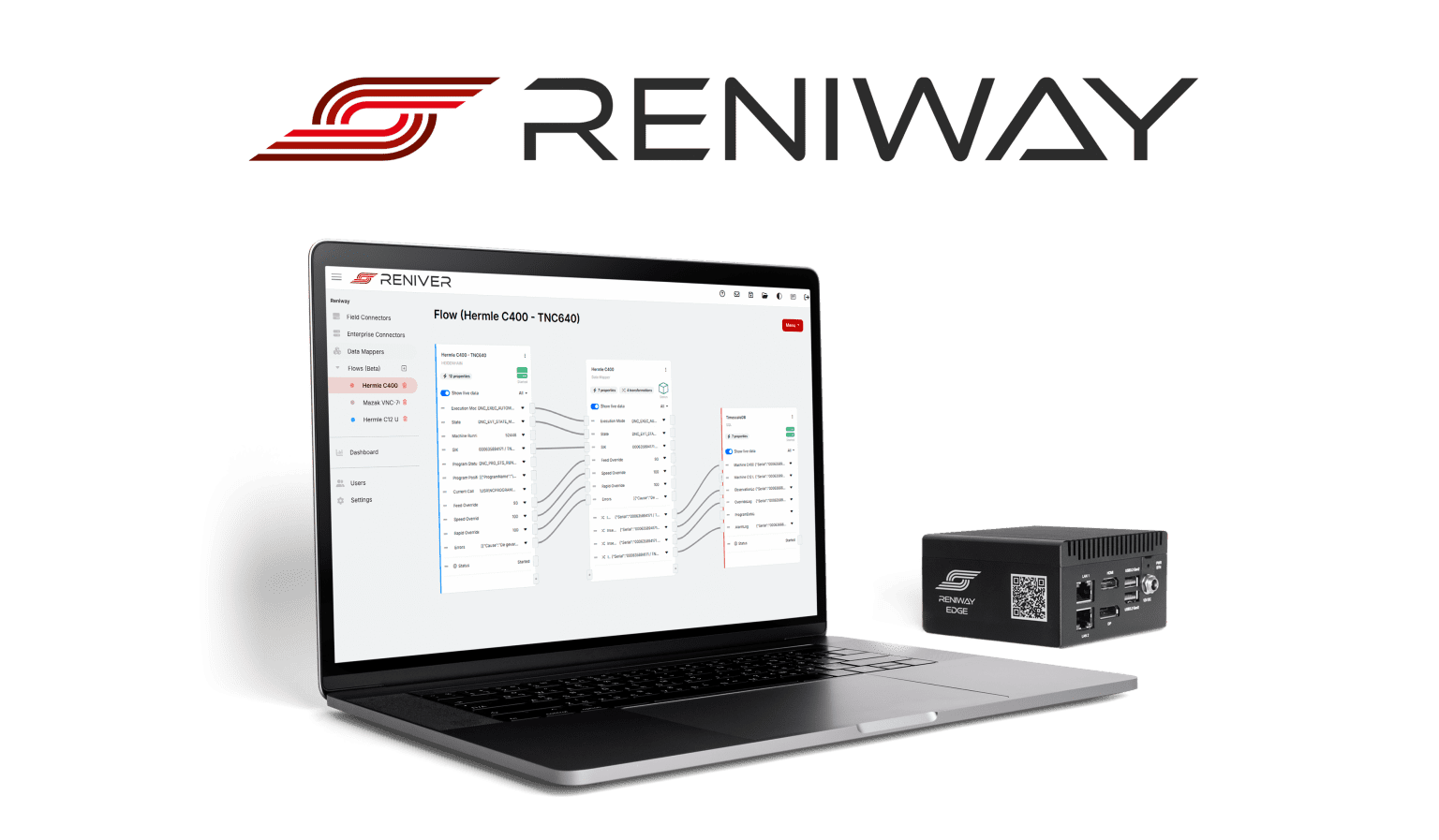

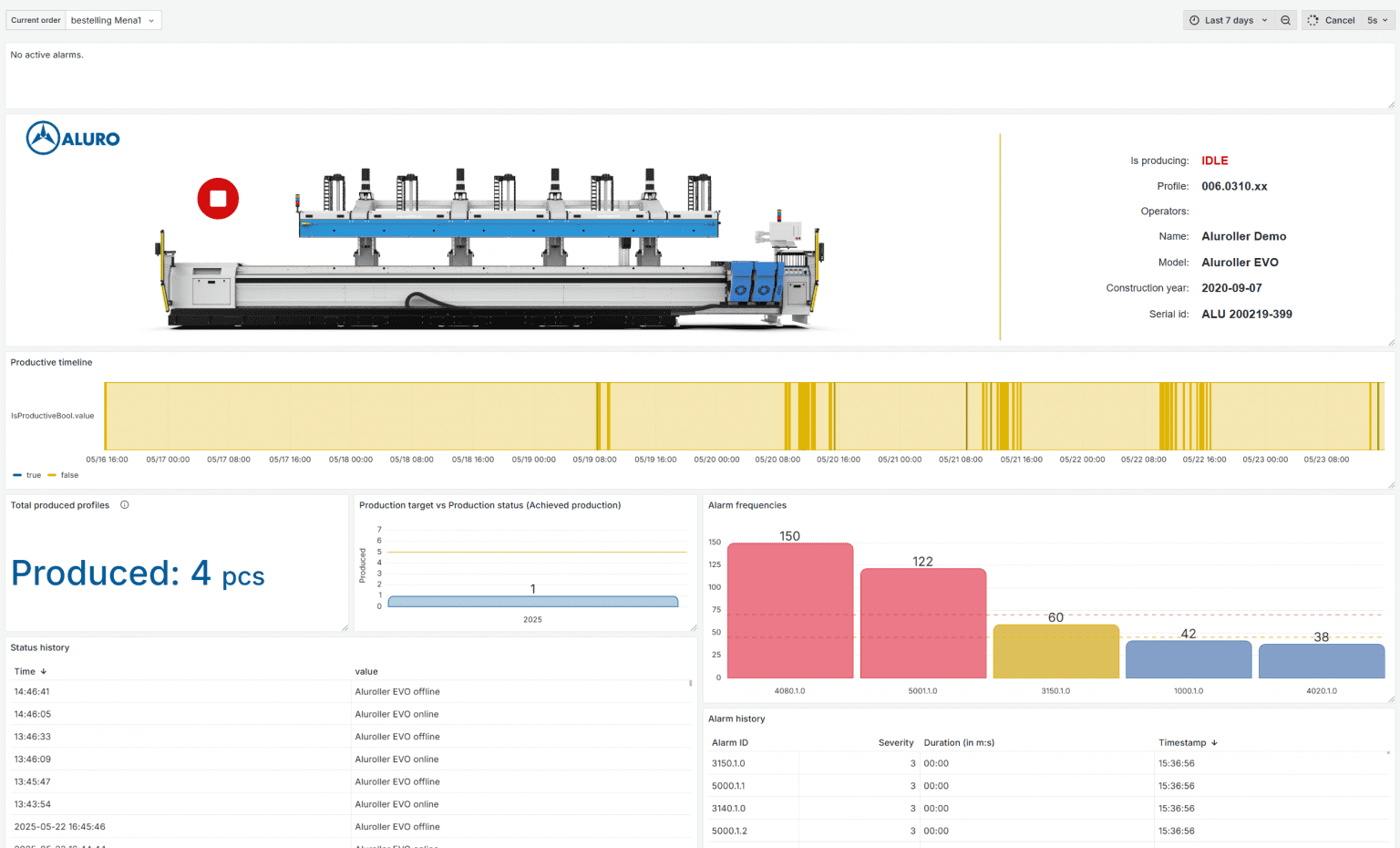

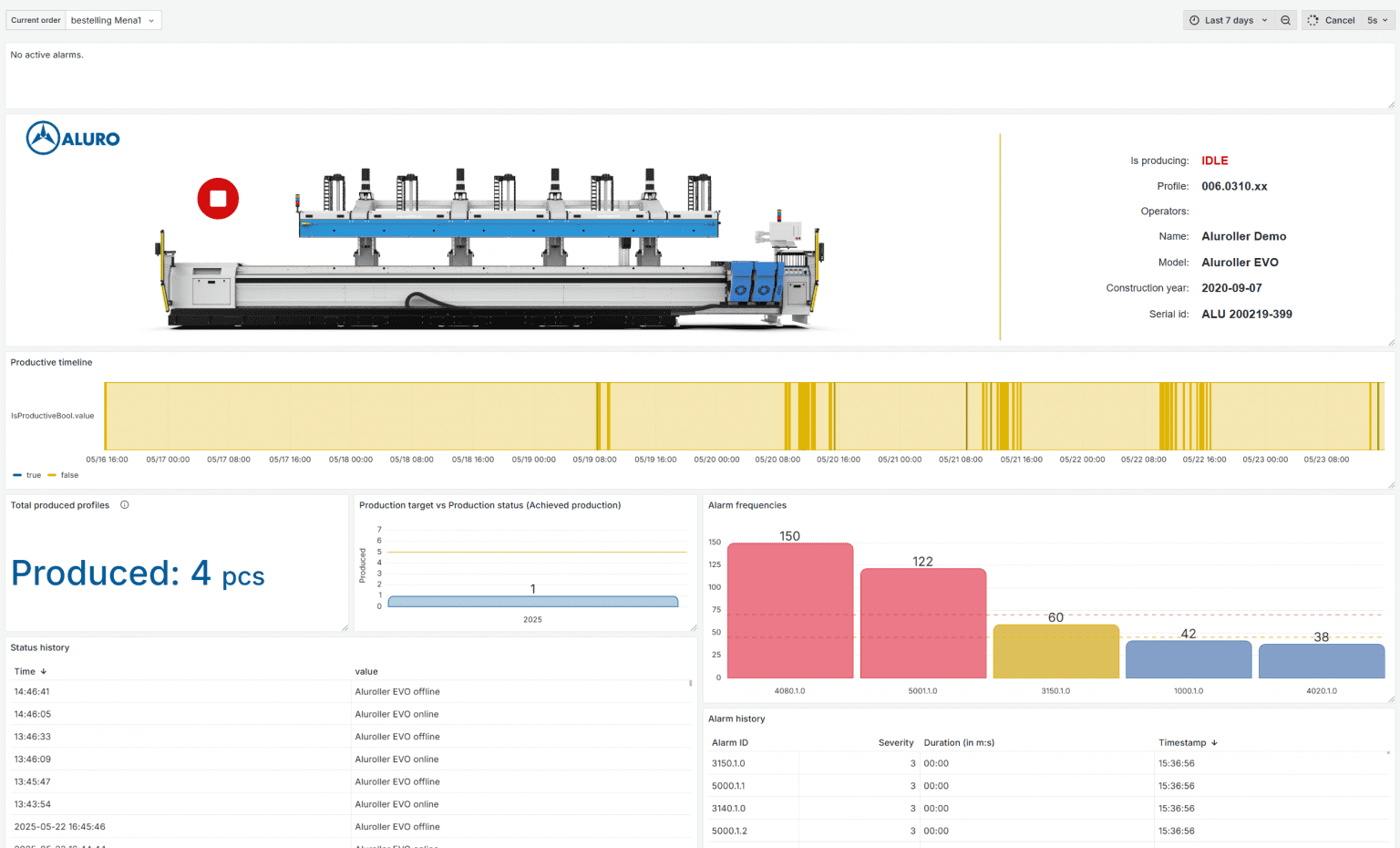

Reniver collaborated with Alluro to integrate the Reniway Edge platform into their new machines. This involved installing the Reniway IPC, which allowed data collection from multiple machines on a single network. Using open standards like OPC Unified Architecture, the solution ensured compatibility with various industrial systems.

The new smart interface enabled real-time monitoring of key metrics such as Overall Equipment Efficiency (OEE), condition monitoring, and energy use. Additionally, features like remote diagnostics and predictive maintenance were implemented, allowing Alluro to offer more efficient after-sales support and streamline machine maintenance.

Reniver collaborated with Alluro to integrate the Reniway Edge platform into their new machines. This involved installing the Reniway IPC, which allowed data collection from multiple machines on a single network. Using open standards like OPC Unified Architecture, the solution ensured compatibility with various industrial systems.

The new smart interface enabled real-time monitoring of key metrics such as Overall Equipment Efficiency (OEE), condition monitoring, and energy use. Additionally, features like remote diagnostics and predictive maintenance were implemented, allowing Alluro to offer more efficient after-sales support and streamline machine maintenance.

By implementing the Reniway Edge platform, Aluro achieved their objectives and more:

By implementing the Reniway Edge platform, Aluro achieved their objectives and more:

What can you expect?

Become Reniver’s C++ master! Work closely with real machines, industrial equipment, and real-time systems like PLCs or RTOS edge devices. Design, build and maintain high performance microservices that capture, transform, and store data from industrial controllers, IoT devices, robots, etc. By using model-based design and tools you turn data models into generated code fast-tracking your development. Your code will be reviewed, built, tested, and deployed using Gitlab DevOps tooling, Linux, and Docker technology.

Your profile

We are always on the lookout for Mister Jack, the Jack of all trades. However, if you are familiar with any of the technologies listed below, please feel free to contact us:

Or if you’re looking to learn any of these skills quickly, we invite you to apply now!

Full-Stack Developer | C# .NET Angular

What can you expect?

Become the star developer of our state-of-the-art Reniway application! Design and implement microservices with REST APIs, IoT communication services and function blocks for our low-code platform using C# .NET6. A nicely built and architected backend goes hand-in-hand with a great user experience, for which you will develop the Reniway UI Angular 15 with Material app. Your code will be reviewed, built, tested and deployed using our Gitlab DevOps tooling and Docker technology.

Your profile

We are always on the lookout for Mister Jack, the Jack of all trades. However, if you are familiar with any of the technologies listed below, please feel free to contact us:

Or if you’re looking to learn any of these skills quickly, we invite you to apply now!

Data Engineer | Digital Manufacturing Platform | Lier

Wat kan je verwachten?

Je werkt mee aan onderzoek en ontwikkeling van een innovatieve “Industrie 4.0” oplossing die productiedata slim inzet om efficiënter te produceren en proactieve acties te nemen om stilstand te verminderen. Het kantoor ligt bij het pittoreske centrum van Lier en is goed bereikbaar via openbaar vervoer. Je komt terecht in een informele werksfeer met een jong en gedreven team. Je werkindeling bepaal je zelf en thuiswerk is helemaal ingeburgerd.

Jouw profiel

Onze witte raaf kan alles, maar ben je vertrouwd met 1 of meerdere van onderstaande technologieën, aarzel dan zeker niet om ons te contacteren:

of enkele van deze skills snel wil bijleren. Dan nodigen we jou graag uit om te solliciteren!

Devops | Digital Manufacturing Platform | Lier

Wil je graag werken in de wereld van machinebouwers, smart factories en Industrie 4.0? En zie je jezelf groeien in een jonge onderneming vol enthousiasme, waar je de kans krijgt om je huidige software skills verder te ontwikkelen?

Dan willen we je leren kennen!

Wie zijn wij?

Een innovatief technologiebedrijf dat oplossingen biedt om machinebouwers en productiebedrijven klaar te maken voor de connected future. Onze ingenieurs en programmeurs realiseren projecten die bestaan uit een combinatie van consultancy, software ontwikkeling op maat en ons in-house ontwikkeld product (machine connectivity platform). We hebben sterke groeiambities en zijn daarom op zoek naar meerdere ontwikkelaars.

Wat kan je verwachten?

Je werkt mee aan onderzoek en ontwikkeling van een innovatieve “Industrie 4.0” oplossing die productiedata slim inzet om efficiënter te produceren en proactieve acties te nemen om stilstand te verminderen. Het kantoor ligt bij het pittoreske centrum van Lier en is goed bereikbaar via openbaar vervoer. Je komt terecht in een informele werksfeer met een jong en gedreven team. Je werkindeling bepaal je zelf en thuiswerk is helemaal ingeburgerd.

Wat bieden we aan?

Een aanstelling met een voltijds contract, een goede verloning met extra legale voordelen. Twaalf ADV dagen boven op je wettelijk verlof. Je werkt zelfstandig in alle flexibiliteit. Verder kan je genieten van een ruim opleidingsbudget op maat om je start optimaal te begeleiden. Je bouwt aan de groei van het bedrijf en deelt in het succes.

Jouw profiel

Onze witte raaf kan alles, maar ben je vertrouwd met 1 of meerdere van onderstaande technologieën, aarzel dan zeker niet om ons te contacteren:

of enkele van deze skills snel wil bijleren. Dan nodigen we jou graag uit om te solliciteren!